Carbide Rods are cylindrical alloy materials made by powder metallurgy process. According to the cutter use requirements, there are solid round bars for external cooling cutters, with single or double straight holes or spiral holes for internal cooling cutters. It is widely applied to cutter materials, such as milling cutters, drills, reamers, etc., which are used to cut cast iron, non-ferrous metals, plastics, chemical fibers, graphites, glasses, stones and ordinary steels, and it also can be used for cutting heat-resistant steels, stainless steels, high manganese steels, tool steels and other materials difficult to be cutted.

Carbide Rods have stable mechanical performance with extremely good hot hardness, good wear resistance, high elastic modulus, high bending strength, good chemical stability (acid, alkali and high temperature oxidation resistance), good impact resistance toughness and low expansion coefficient.

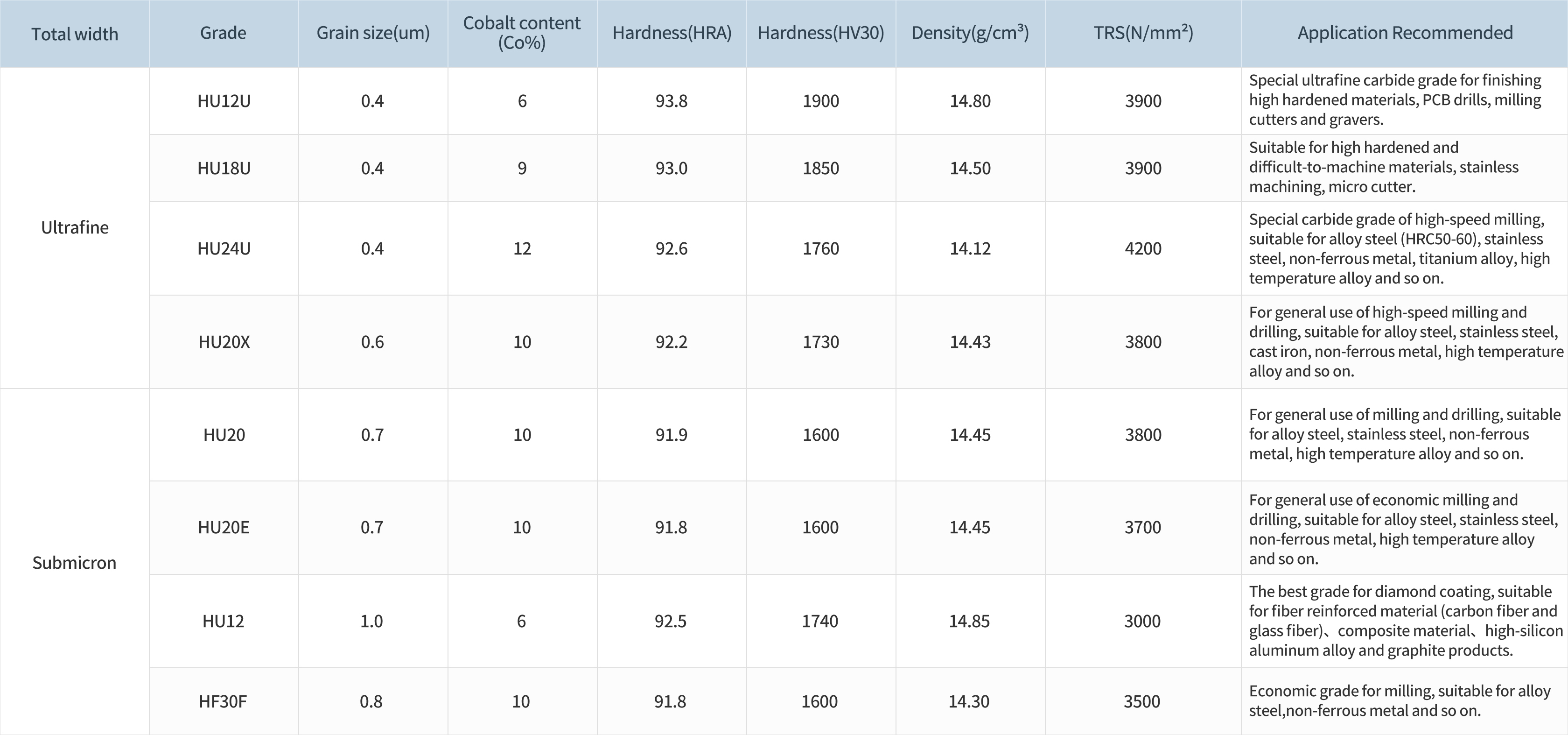

We can also produce many other kinds of carbide for customers in addition to the list above.

Automobile Manufacturing: Used for engines, turbine discs, engine bases and other processing tools

3C Electronic Communication Manufacturing: PCB boards, collection shells and other processing tools

Mold Processing: various drilling and milling tools